Services

23.11.2015

Control with LC display power supply 12V LCD display 2x16 characters user menu ...

24.11.2015

We propose production of cables and cable harnesses made-to-measure acoording to customer's wishes including assembly of cable boots and connectors. We provide production of simple, shielded and multicore cables.

24.11.2015

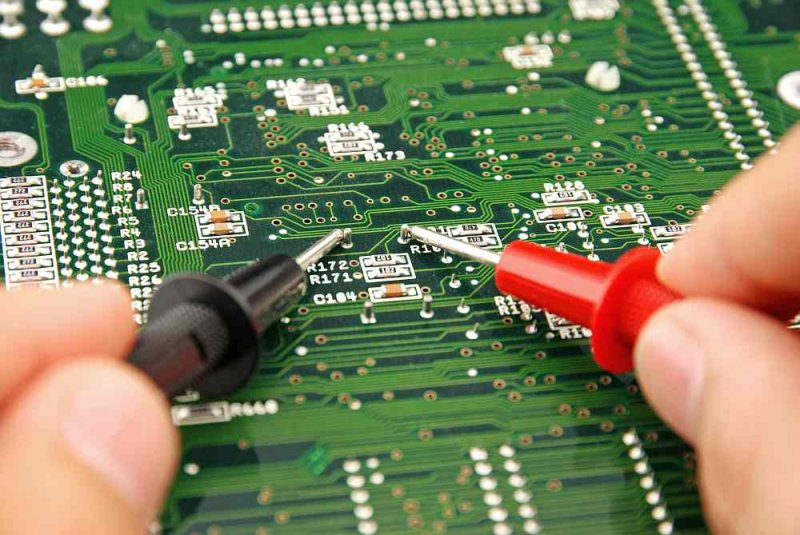

Production can range from a single piece to medium and large batches. During production, surface-mount technology (SMT) and through-hole technology is used (THT). We use Lead-Free welding technology. Welding is done by machines and manually on Weller welding stations.

The entire process takes place in an antistatic environment using bar and 2D codes for monitoring quality during production.

1.1.2016

For creating the software for the applications being developed, our company has professional development resources at its disposal. This guarantees a high level of quality of the technical solution for the project, minimizing the number of errors, reducing development time, and Therefore reducing development costs.

Developers with many years of experience with microprocessor applications in industrial electronics work on the software.

The programming itself is preceded by a comprehensive analysis of the SW solution for the given project. The analysis includes both the functionality requirements and testing methods in connection with production, installation and servicing of the equipment. Based on the extensive analysis conducted, the software for the application in question is carefully programmed. This approach guarantees clarity of the SW, reduces the time necessary for your own programming, and allows modification and the addition of new functions.

1.1.2016

All products undergo exacting test procedures and development quality control. When testing, a team of specialists carry out a series of measurements to ascertain whether the tested equipment corresponds to the requirements set out in the technical terms of reference.

Development work is supported by our own sample production of printed circuits. In this way, we are able to manufacture a sample to quickly verify the connection. It is also possible to produce a two-layer printed circuit board. For this purpose, our development facility is equipped with a modern ProtoMat S43 engraving machine from LPKF Laser & Electronics.

This step is followed by the production of a verification batch, which is tested in a real environment. This is done to verify the components used and to fine-tune the technical parameters. Should discrepancies arise that could not have been ascertained beforehand, the products are further fine-tuned.

2.1.2016

The design of a new piece of equipment is comprised of a number of basic steps that are sequential or run in parallel with the technical terms of reference, providing an optimal solution in terms of the requirements being sought at the time that the terms of reference are being defined.

First, a connection diagram is created. This diagram makes use of components that fulfil the minimum requirements of the terms of reference or, better yet, have a certain reserve for any future expansion.

According to the specific requirements of each application is chosen a corresponding microsequencer. We modify the choice to the kind of application to achieve the best results both with regard to functionality and with regard to the price-to-performance ratio.

Once the elementary solution is approved, a printed circuit board (PCB) is designed. The printed circuit design is conformed to the requirements of the technical terms of reference, the positioning of the connection points, the size requirements of the equipment, the parts used, the planned production technology, the anticipated number of pieces to be manufactured, the materials used to manufacture the PCB, and so on.

3.1.2016

For a professional result, it is crucial to have clearly specified terms of reference. We perform a needs analysis with our customers and determine all parameters and properties of the required electronics and based on these, we draw up exact terms of reference. Then we propose the input and output elements, the control algorithms and the design.

The quality of the initial analysis – during which all control requirements, possible links and any planned future expansions are checked – guarantees a quality result at the end of the development stage.

If clearly specified terms of reference exist, consulted in detail with the client, it is possible to eliminate complications and ambiguities with the completed sample.

4.1.2016

Protronix s.r.o. is a purely Czech company with a tradition spanning many years. The company supplies its customers with technologically advanced and functional solutions, especially in the fields of measuring, controls and automation technology. These solutions are, as a rule, built on the basis of single-chip microprocessors from various manufacturers.

Protronix works with its customers during the entire development process all the way through to production. Our experts have extensive knowledge and many years of experience in the field of microprocessor application in measuring, controls and automation technology. They will design control electronics tailored to meet the actual technology management needs of our customers.